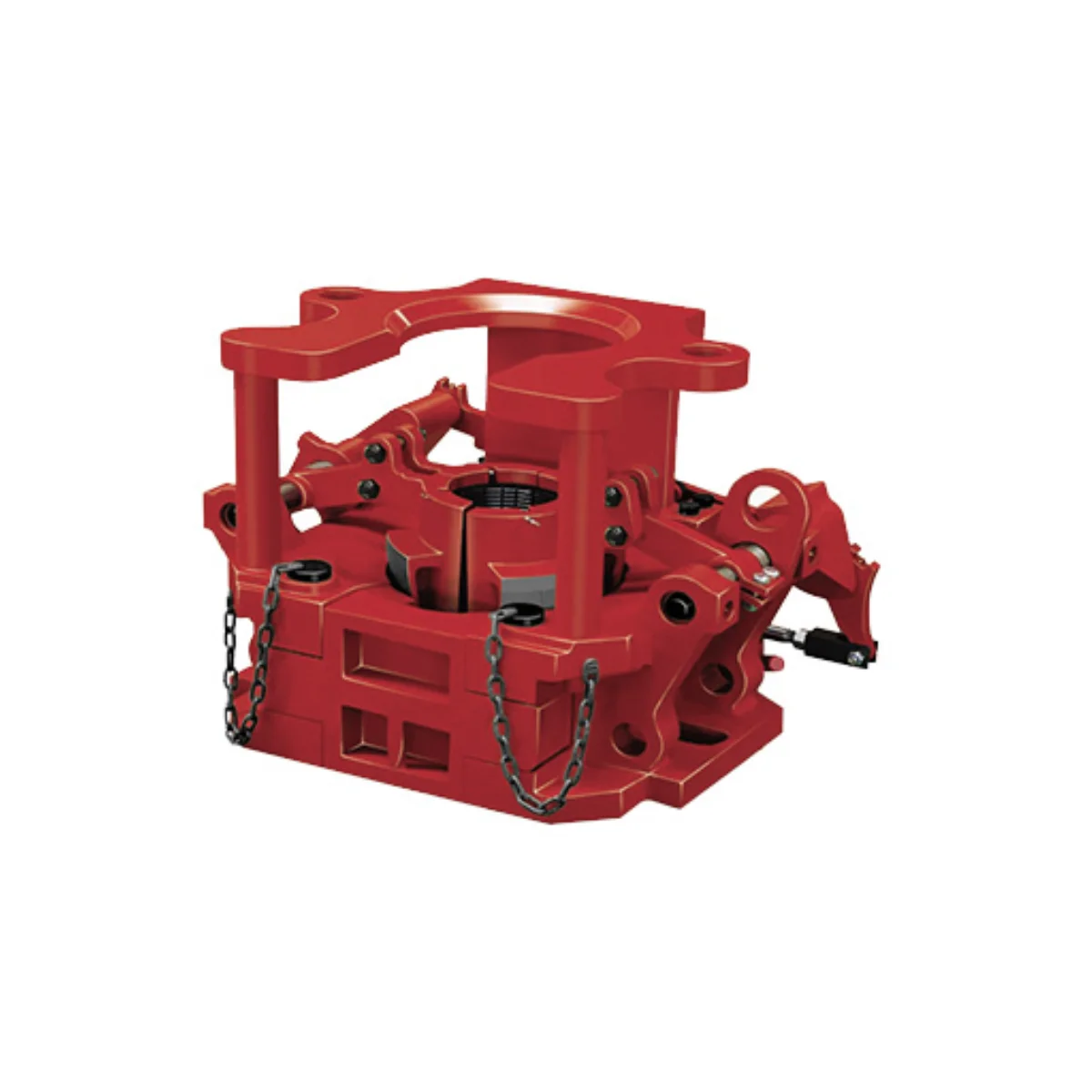

Tubing Spider

Spectrum Drilling Tools International specializes in manufacturing Tubing Spiders, adhering strictly to the API-7K Specification (Latest Edition). Over the years, our spiders have undergone continuous refinement based on extensive experience and testing. This positions us as the leader in ensuring the safe, cost-effective, and trouble-free handling of tubular goods.

We utilize heat-treated alloy steel extensively, maximizing strength and longevity while keeping weight to a minimum. The shafts are made from hardened alloy steel for extended service life. Replaceable steel bushings are integrated into the journal bearings. All bearings and journals come equipped with grease fittings for proper lubrication.

Air Cylinders and Foot Valves receive mist lubrication through the airstream. Each Spider features a manually operated safety latch that serves to securely lock the slips in their set position. Due to the low operating pressure, the slips cannot disengage from the tubing until it has been elevated by the elevators. This design feature serves as a safeguard against accidental tripping of the Foot Valve, preventing the loss of a string.

Guards are in place to shield the Slips, Shafts, and Air Operating Mechanisms from potential damage caused by the elevators or external forces. Our engineers are continuously engaged in research and field testing to identify additional enhancements that ensure field personnel receive the safest and most low-maintenance equipment available.

The Pneumatic Spider is offered in five models: Model “C”, “CHD”, “E”, and “G”. All are designed to support manual, compressed air, or hydraulic operation, with the exception of Model “G” which is available for compressed air or hydraulic operation exclusively.

All Spectrum Drilling Tools International Spiders can be utilized on a rotary table with an adapter plate that fits into the square drive or pin drive master bushing, aligning the Spider on the rotary table. This also allows for manual rotation of the Spider. Models “C” and “CHD” Spiders can be equipped with a Gate and Slips that are designed to accommodate parallel strings of tubing. For Spiders intended to handle both single and parallel strings, we recommend ordering both types of Slips and Gates. A standard feature in all our Spiders is a specially designed Gate Section that enables the concurrent running of an electric submersible pump cable alongside any tubing string of any size.